WASTE WATER

Waste Water Management and Water Analytics South Africa with Prei Instrumentation.

Discover the waste water management and water analytics South Africa process that converts water no longer needed or suitable for use into bilge water that is returned to the environment.

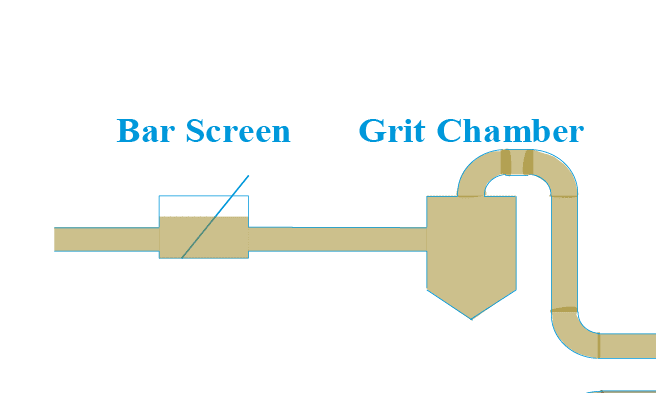

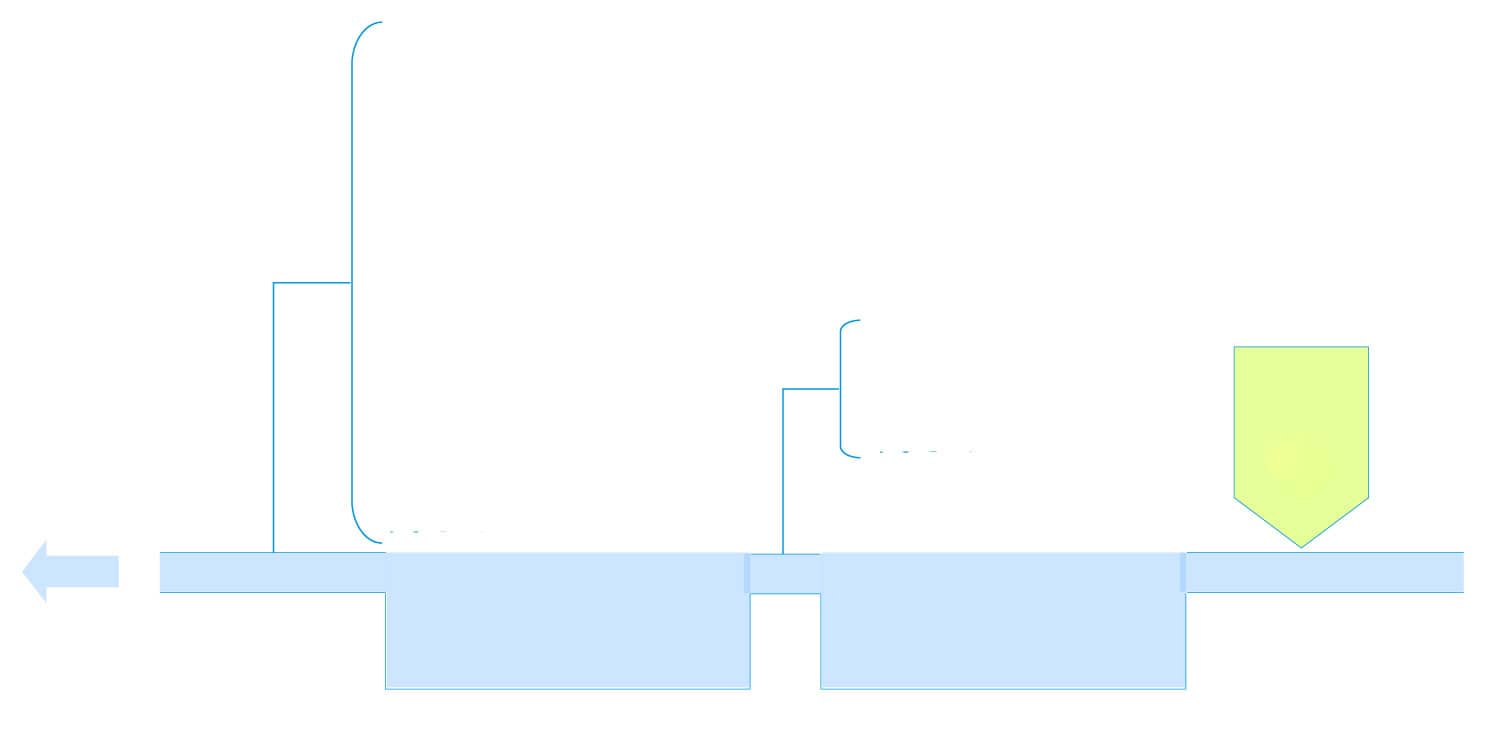

Pre-treatment phase

During the pre-treatment phase, engineers begin by removing large debris, including tree limbs, leaves, garbage, cans, rags, plastic bottles, diapers, and other waste, using bar screens. Then, they direct the water into equalisation basins and grit chambers, which regulate inflow and allow stones, sand, and glass to settle. In addition, these basins store sewage until treatment begins and manage storm-related overflows. Meanwhile, some plants skim grease and fats from the water surface, often using air blowers to create froth for easier removal, while other plants handle grease in the subsequent treatment phase.

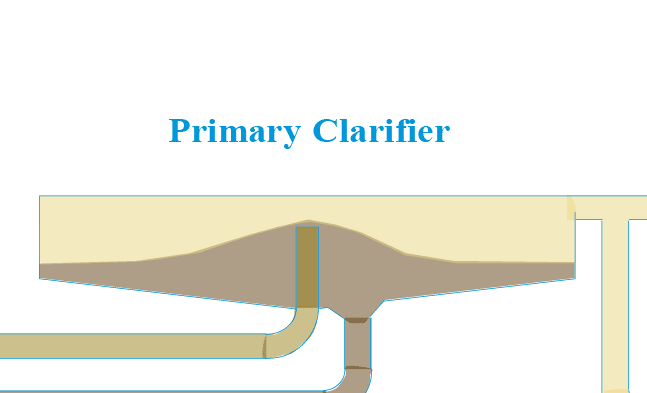

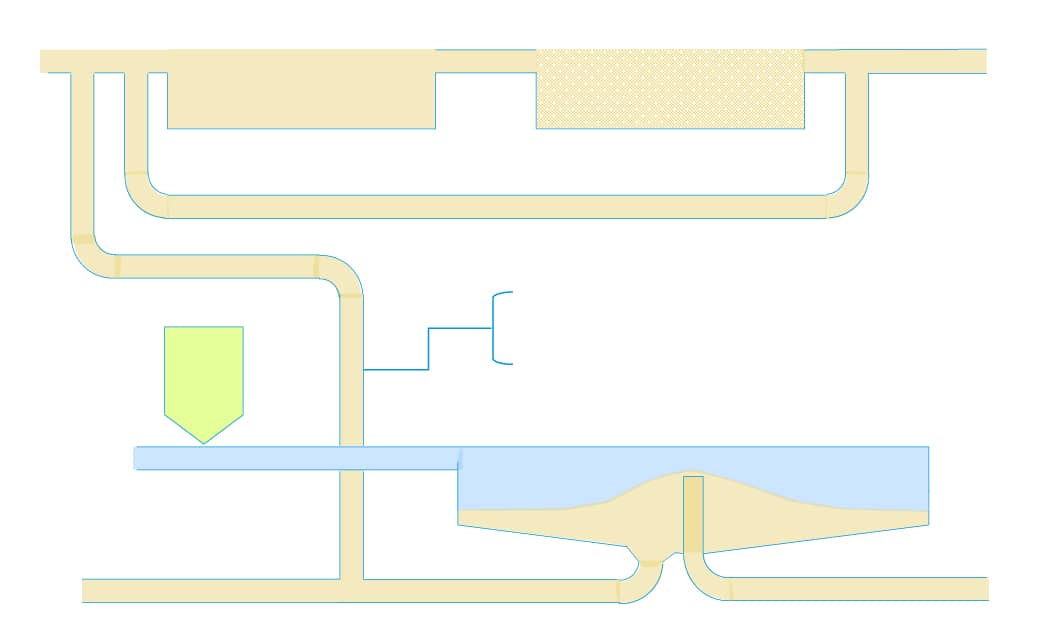

Primary treatment phase

Following pre-treatment, wastewater enters primary clarifiers, which are large basins with sedimentation tanks. As a result, smaller particles settle by gravity, while mechanically driven scrapers collect solid matter and direct it to hoppers connected to sludge treatment equipment. If the plant did not remove grease and oil during the pre-treatment phase, engineers now remove it using surface skimmers. Additionally, some plants process collected fats by combining them with lye, producing soaps and glycerol.

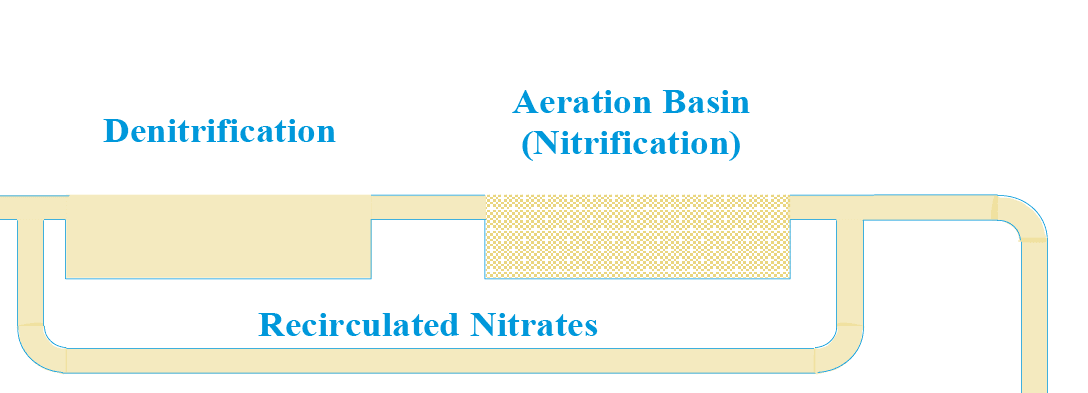

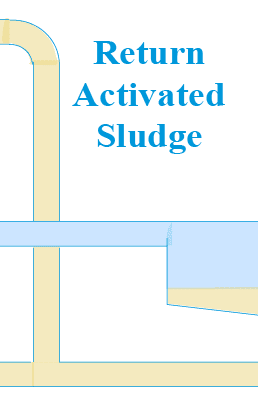

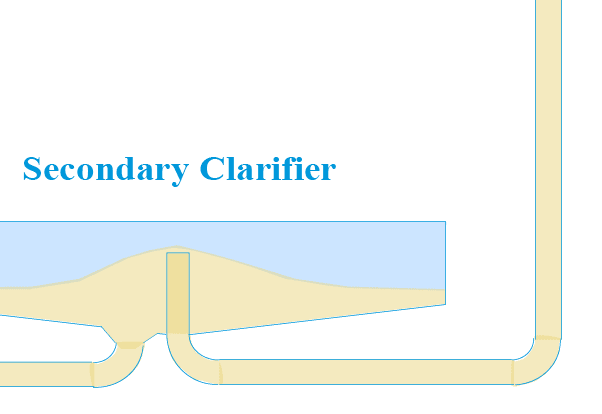

Secondary treatment phase

In the next phase, wastewater treatment plants aerate and agitate the wastewater in secondary basins, adding beneficial microorganisms to break down organic matter into sludge. Plants use various strategies to break down sludge. For example, they can culture many microbes and pass the waste material over the biofilm. Other plants combine biomass with waste to produce activated sludge, which can be recycled and reused. Carbon and nitrogen are removed from organic wastes by the resulting biological floc. Oxidation can occur on the surface, in lagoons, or in filter beds containing coked coal and limestone. Some wastewater treatment facilities build wetlands and reed beds to decompose organic waste. Membrane bioreactors and biological aerated filters are two other technologies used. The wastewater that results collects and settles in a secondary clarifier tank.

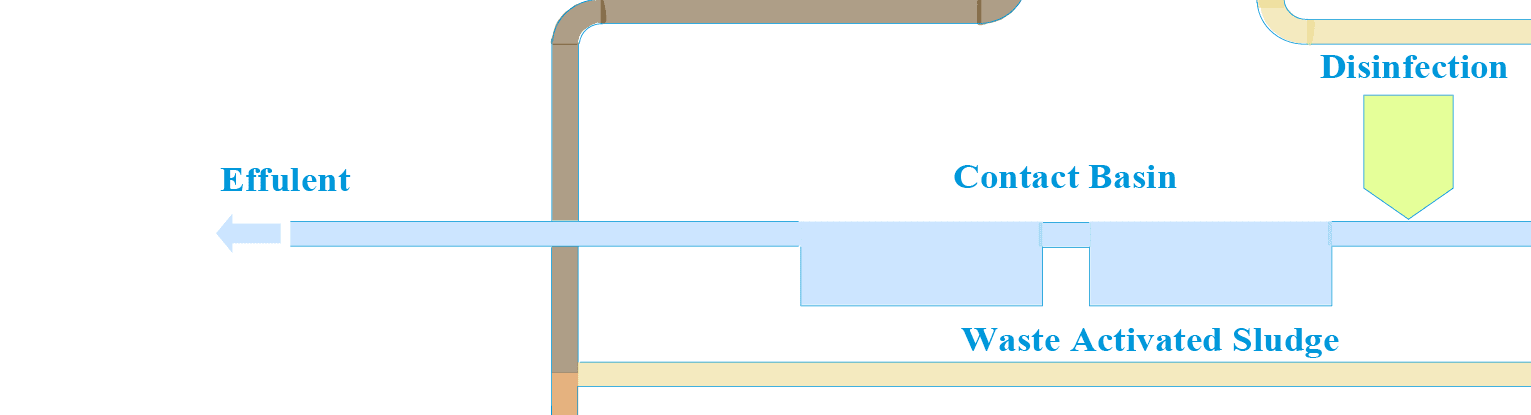

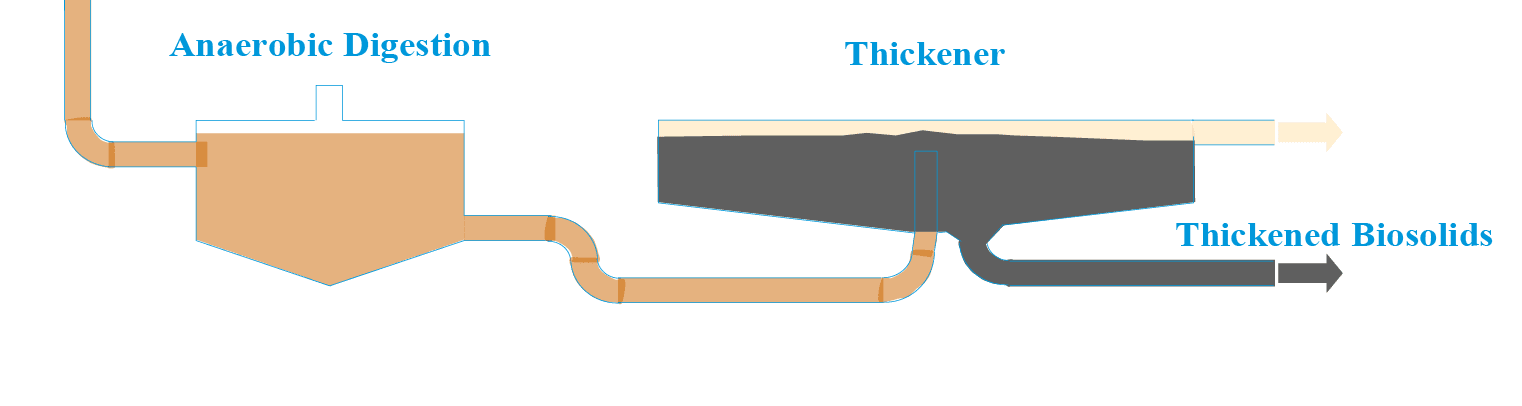

Sludge treatment phase

The final step is to treat the remaining water and biosolids, also known as sludge. Organic waste is separated from heavier grit by gravity and can be disposed of in landfills. After passing through a thickener, the remaining primary sludge is centrifuged and fed to digesting tanks containing anaerobic bacteria. These tanks generate methane, which is used to power the plant. The final solid product, stabilised sludge, can be partially deodorised and used as fertiliser in the soil. The remainder of the wastewater is treated to remove phosphorus, nitrogen, and other nutrients before being disinfected with chlorine, ozone, or ultraviolet light and returned to the water supply.